While perfectly suited for analytic surfaces, solid features and the like, they can’t handle complexity.ĭelcam’s ArtCAM has been on the market for almost 20 years and it has been serving its industry niche very well. And its here that the mainstream 3D design tools let us down.

So that your tool avoids any clamps that you may use to hold the material in place when machining, you can enter in the required height above the surface of the material at which it is safe to move the tool at rapid speeds between toolpath segments.The Contour Blend tool creates previously unattainable centreline ridged or smooth domed shapes ideal for stylised engraved textįor instance, in the structural packaging, signage or jewellery industries complex geometry is often the name of the game. Additionally you can opt for your preferred machine tool cutting direction (clockwise or anticlockwise). Machining parameters such as the speeds and feeds can also be amended to accommodate for your CNC machines’ capabilities and to allow for varying material hardness. To give you the best machining finish, ArtCAM’s Feature Machining also gives you the choice of machining the feature from the centre of the cutting tool or from its edge. To ensure that the cutting tool creates a clean crisp edge where your feature or text joins the relief, you can sharpen the edges of the feature so that the cutting tool goes into the tightest of corners. Working with the geometry of your cutting tools you can not only determine the width but also the shape and definition to both the top and bottom of your feature. This will preserve the contour of your relief.

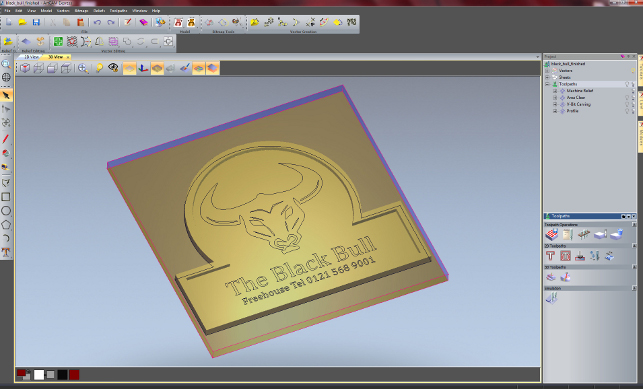

Working with your selected vectors or vector layer (provided you have purchased the Vector Tools Module) you can machine raised, recessed or centreline engraved features to a depth or height relative to your ArtCAM Relief Clipart or imported 3D model. This module is ideal if you wish to engrave text or imagery over a curved surface, for example some text on a three dimensional sign or shield. ArtCAM Express - Feature Machining Module

0 kommentar(er)

0 kommentar(er)